Industrial wastewater treatment is the process of treating water

discharged from manufacturing

and industrial operations to remove harmful pollutants before release or reuse. Each industry

produces a unique type of wastewater, requiring specialized treatment technologies.

> HDCOP View

At HDCOP for Engineering, we offer custom-designed solutions for a wide range of

industrial sectors, ensuring compliance with environmental regulations and enabling water

recovery, reuse, or safe discharge.

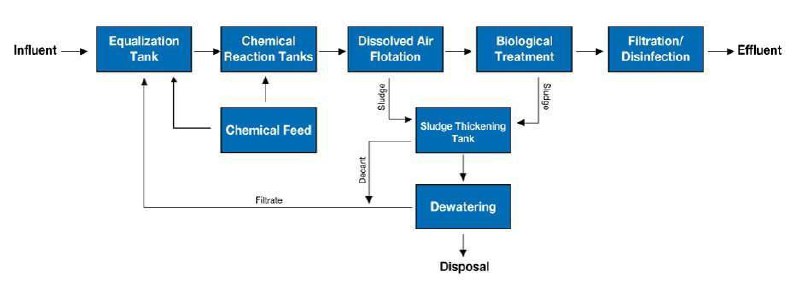

• Typical Wastewater Treatment Process Includes:

1. Pre-Treatment

- Screening: Removes large solids like plastics, rags, and debris.

- Equalization Tanks: Balance flow and load variations.

- Oil & Grease Removal: Separators or remove free oils and fats.

2. Primary Treatment

- Chemical Coagulation & Flocculation: Addition of chemicals to aggregate suspended solids.

- pH Adjustment: Neutralization of acidic or alkaline effluents.

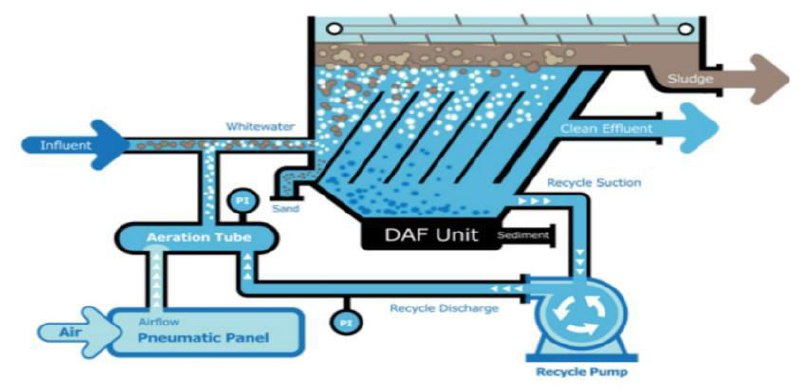

- Reducing TSS : Separators or Dissolved Air Flotation (DAF) units .

3. Secondary (Biological) Treatment

- Activated Sludge or MBBR/MBR Systems: Biologically remove biodegradable organics.

- Anaerobic Treatment (if high-organic load): Reduces sludge production

- Settling/Sedimentation: Solid-liquid separation of flocs.

4.Tertiary Treatment (Advanced)

- Filtration & Adsorption (e.g., activated carbon): Remove remaining pollutants.

- Heavy Metal Removal or Advanced Oxidation (AOP): For hazardous compounds.

- Disinfection: Ensures water is free from pathogens for reuse or discharge.

5. Sludge Treatment & Disposal

- Dewatering and safe handling of toxic or hazardous sludge.

>Industries We Serve:

- Food & Beverage Processing

- Petrochemicals & Oil Refineries

- Textile & Dyeing

- Pulp & Paper

- Pharmaceutical & Chemical Plants

- Power Generation & Heavy Industry

•Scope of Supply for Industrial Wastewater Treatment

At HDCOP, we provide a complete range of products, services, and solutions to design, build, and

operate wastewater treatment plants.

a. Design and Engineering

b. Equipment and Technologies

- Primary Treatment: Bar screens, grit chambers, and primary clarifiers, DAF System,OGS.

- Secondary Treatment: Activated sludge systems, MBBR, SBR, and MBR.

- Tertiary Treatment: Sand filters, membrane, and disinfection systems (UV, ozone, chlorination).

- Sludge Treatment: Thickeners, digesters, centrifuges, and belt presses.

- Pumps, Blowers, and Mixers: for aeration, mixing, and fluid transfer.

Dissolved Air flotation (DAF)